Leaders in Insulation

Re-engineering rock for over 80 years ROCKWOOL is a committed innovator and a market leader for stone wool insulation.

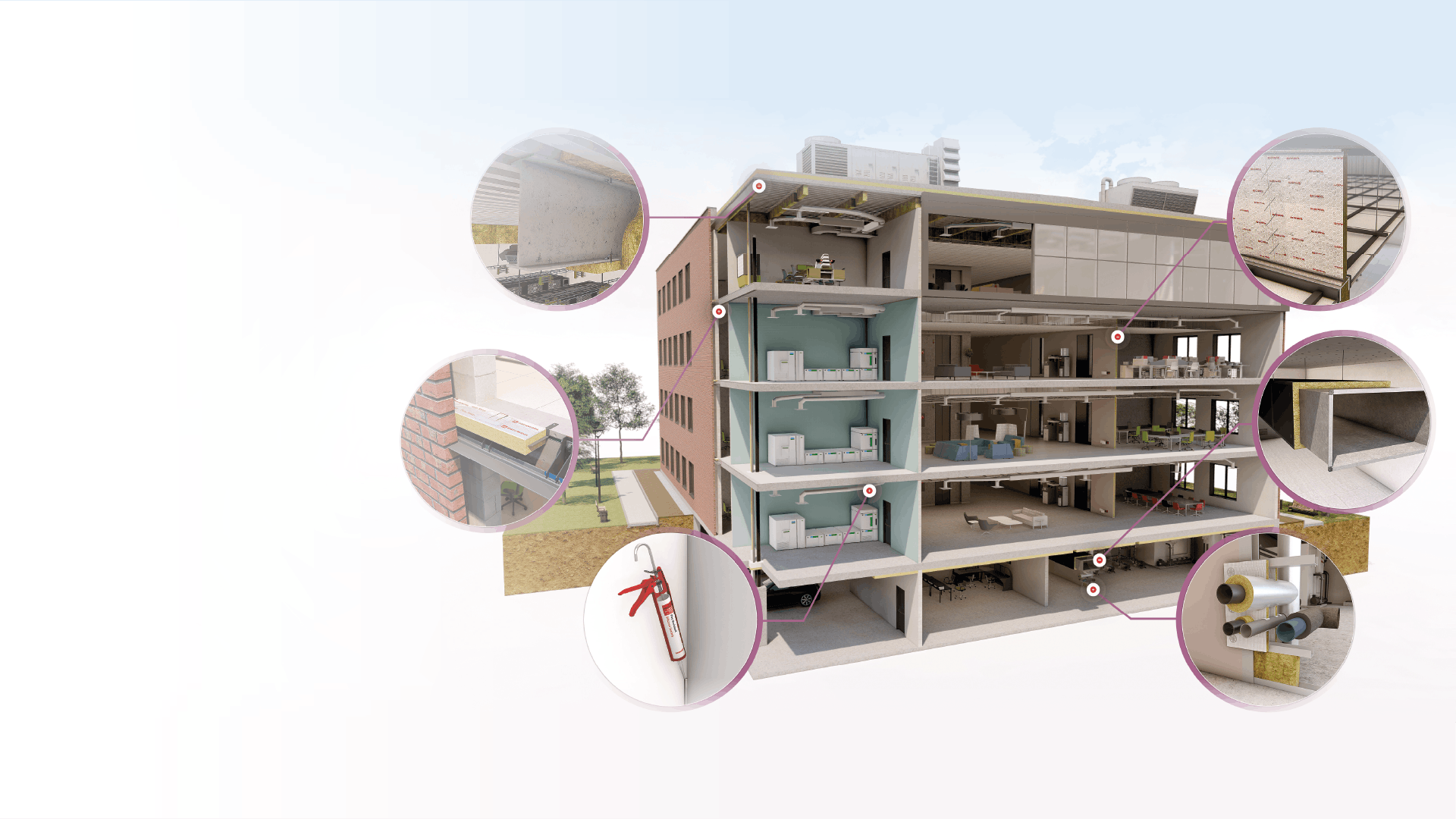

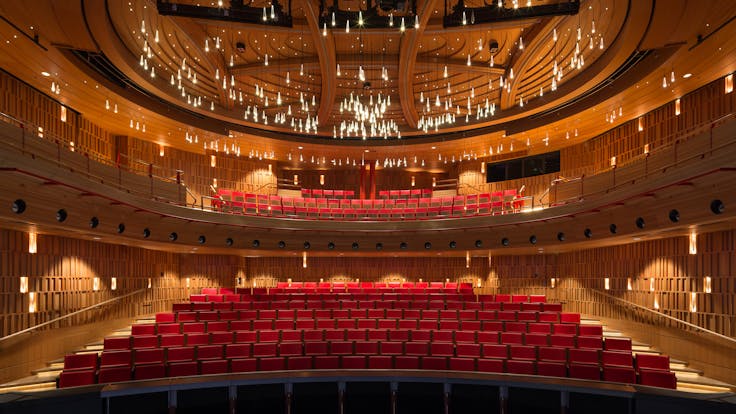

ROCKWOOL stone wool insulation delivers long-term, proven performance for thermal, acoustic and fire-resistant applications.

These benefits are underlined by an unswerving dedication to sustainability. In its lifetime ROCKWOOL insulation will save around 100 times more carbon dioxide than is emitted during its production.